Cladding

Cladding can be described as the welding of two materials with different qualities. A high-quality material can be clad on a cheaper base material in order to increase the erosion and corrosion resistance of a product: this is a good alternative for expensive duplex materials. Cladding (surfacing) is also applied to increase the mechanical qualities.

Delta Controls started with cladding of Stellite on valve parts for the petrochemical industry. This to increase the durability of the parts. We now have many years of experience in cladding for the petrochemical industry and also in the steel, paper, glass (fibre) producing and supplying industries.

Quality

The quality requirements on cladding are usually very high because it is mostly safety related. Delta Controls has the experience and knowledge to meet the highest standards of TÜV, ASME and Stoomwezen and the specifications of the customer. For example: degree of binding, percentage ferrite, hardness, chemical composition, cracking.

New parts and repair

Cladding is applied on new parts as well as to repair old parts. Worn out parts can be used for a second lifetime by applying the right cladding materials. Repairing old parts instead of buying new parts, is both economically and qualitatively a very interesting option.

CNC Welding

Computerized Welding Services

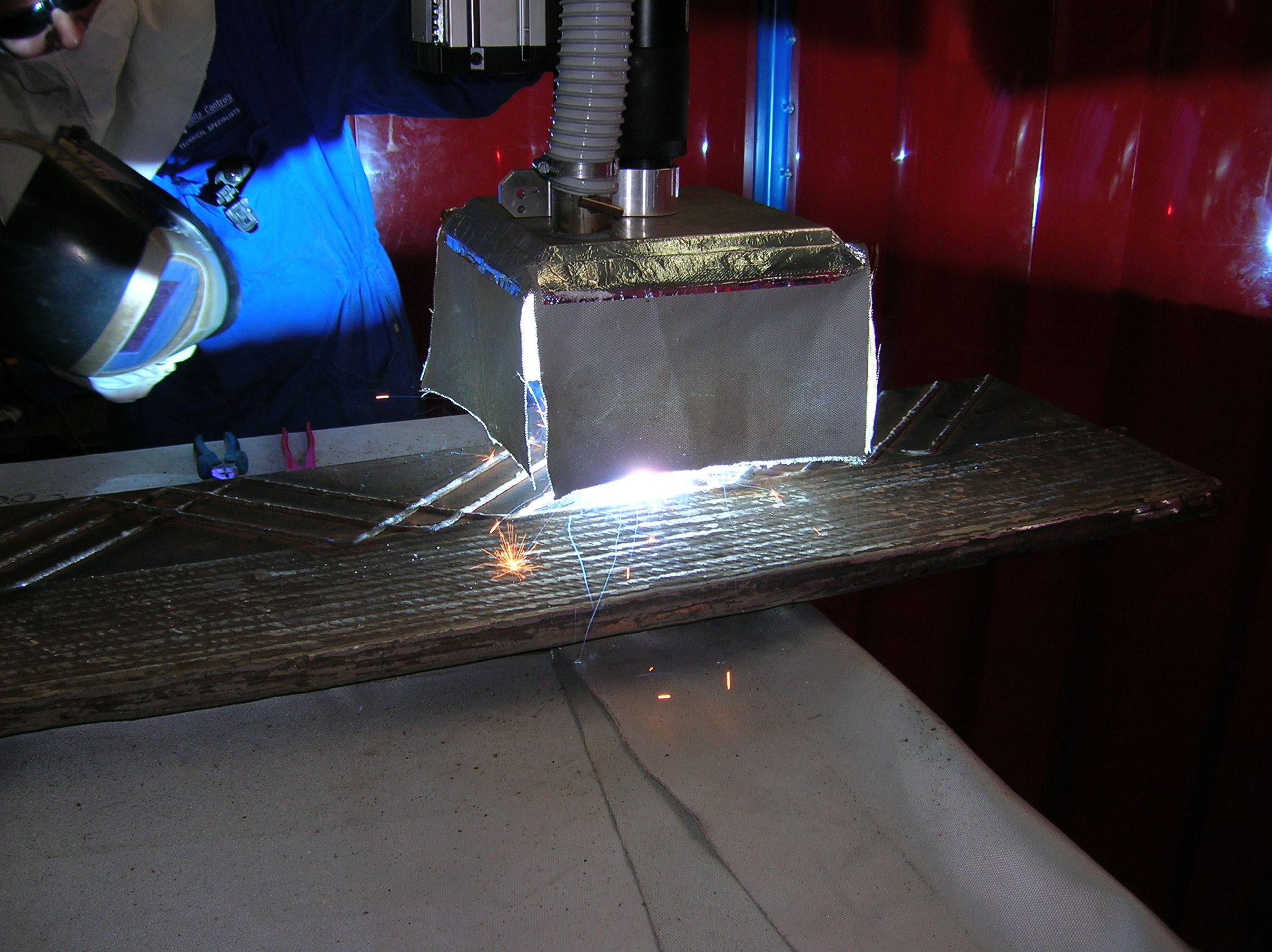

The Delta Controls Robotic CNC welding machine is completely engineered, build and installed by Delta Controls.

Capabilities

Our CNC welding machine is capable of many services like:

- Exceptional precision

- High repeatability

- Multiple axis movement

- Welding all kinds of hard facing alloys

- Continuous seam welding

- Manufacture of prototype or production components

- Flexibility for single or multiple quantities

- Experienced-based selection criteria for surfacing alloy and process selection

- Quality assurance to international standards

- material certification

Process Control and Monitoring

Our CNC equipment offers feedback control to ensure that programmed parameters is delivered to the weld. The feedback loop continuously controls the quality by comparing the programmed levels.

Our database which is used for Metallographic analysis is essential to gathering information to prevent cracks in the weld nugget or in its vicinity. Cracks are not acceptable under any circumstances. To compare former projects, we expand our expertise for our customers.